By Chris Godden, Senior Solutions Engineer, Apromore from Salesforce

Process improvement is a critical aspect of business operations, and many organizations have embraced the Lean Six Sigma methodology to achieve operational excellence. Apromore from Salesforce is a powerful process mining solution that helps practitioners to identify bottlenecks, streamline workflows, and ultimately deliver more value to their customers and shareholders. It is an intuitive, powerful platform that has proven to be the perfect accompaniment to use with the Lean Six Sigma methodology.

Apromore from Salesforce allows organizations to visualize, analyze, simulate and monitor their business processes. The platform enables users to extract data from a variety of sources, including any transactional systems, audit logs, data warehouses and data lakes, as well as desktop applications. It then uses this data to create visual representations and statistics of the business processes, which can be analyzed to identify inefficiencies such as sources of waste, and opportunities for improvement.

The Lean Six Sigma methodology is a structured approach to process improvement that aims to eliminate waste and improve quality and efficiency. It involves five phases: Define, Measure, Analyze, Improve, and Control (DMAIC). In this blog post, we'll take a brief look at how this methodology can be used in conjunction with Apromore from Salesforce process mining to achieve process excellence.

Define

The first step in using Apromore from Salesforce to improve processes using Lean Six Sigma is to define the problem. This involves identifying the process that needs to be improved and establishing the scope of the project. Despite the common perception that process mining is used to only analyze procure-to-pay or order-to-cash processes, typically neither of these processes will likely greatly improve your business, especially in the service industry. Lean Six Sigma and process mining can be applied to any process, whether customer facing, manufacturing, logistics, sales or internal process like hiring or the before mentioned procurement and order processing.

Measure

Transactional data extracted from any system that is involved in the execution of the process can be ingested into Apromore from Salesforce, to create an event log which provides the starting point for Apromore from Salesforce to build a visual representation of the selected process. Specifically, Apromore from Salesforce provides a dedicated ETL tool to join and transform data from multiple sources, to create an end-to-end process.

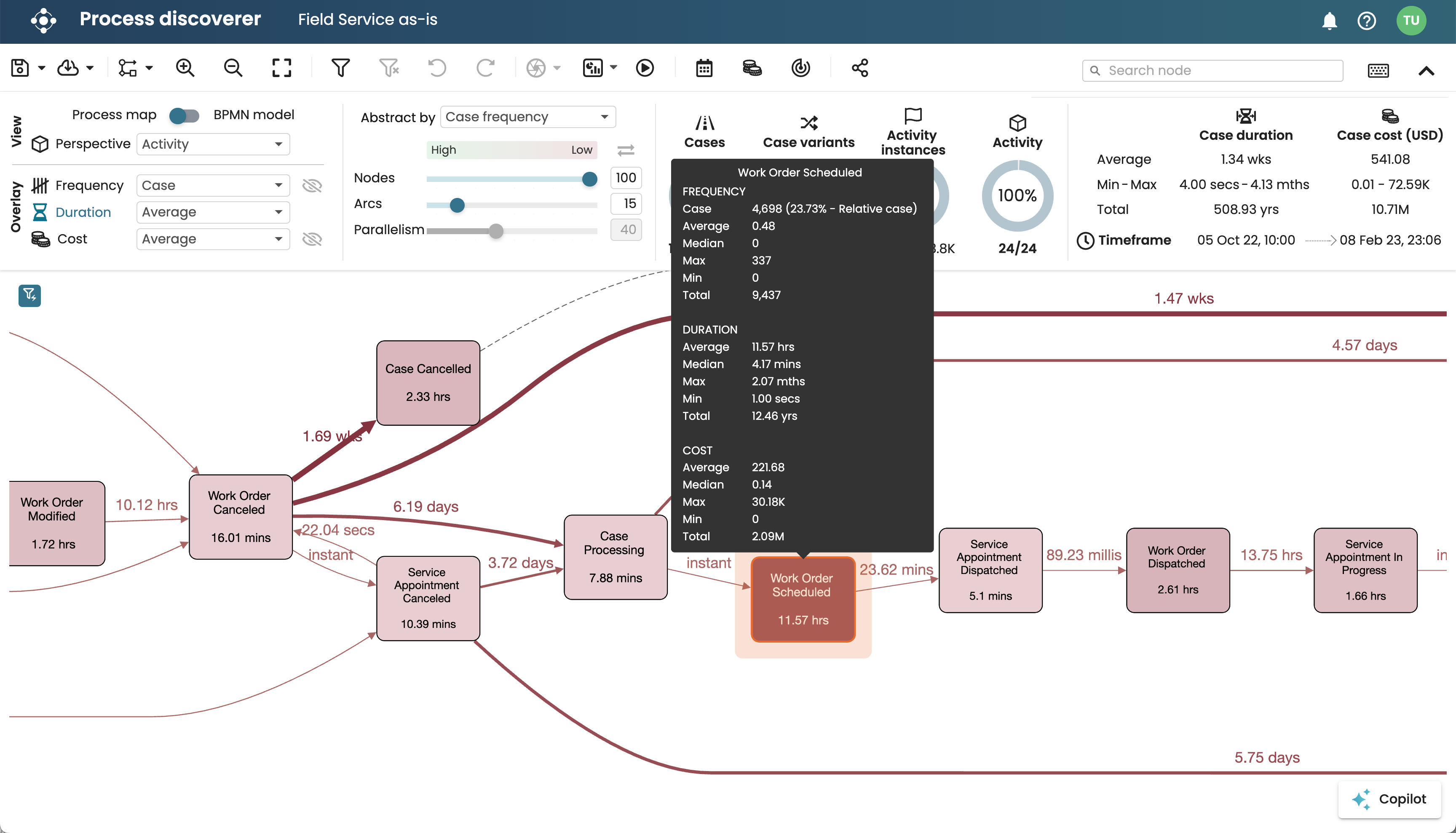

Once the data has been prepared and ingested into Apromore from Salesforce, the underlying process is automatically discovered, and represented in the form of a process map (value stream map) or BPMN model.

The performance of the process can be measured in a number of ways, depending on the project objectives. One can focus on the volume of work (e.g. number of cases flowing through the various activities and transitions connecting tasks, to highlight rework waste), durations (to highlight both activity bottlenecks and resource-capacity bottlenecks, as well as long waiting times) and costs (to highlight overprocessing and rework cost).

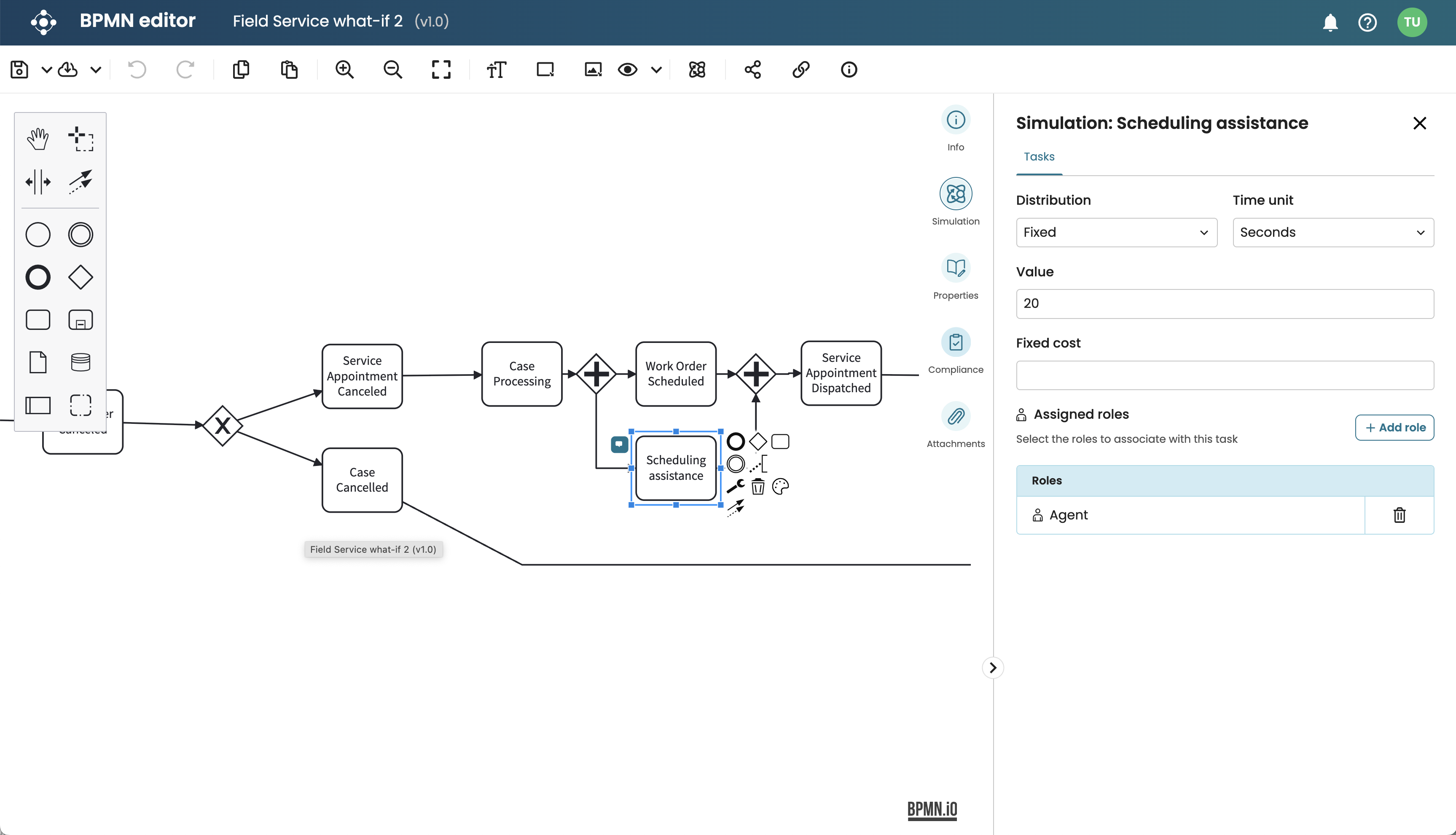

Apromore from Salesforce also has a built-in process modelling suite. Models can either be created automatically from the process data, imported from legacy modelling solutions using the BPMN 2.0 standard or build from scratch within Apromore from Salesforce. This allows for a combination of data and experience based models to enhance analysis far beyond manual Lean Six Sigma measuring.

Analyze

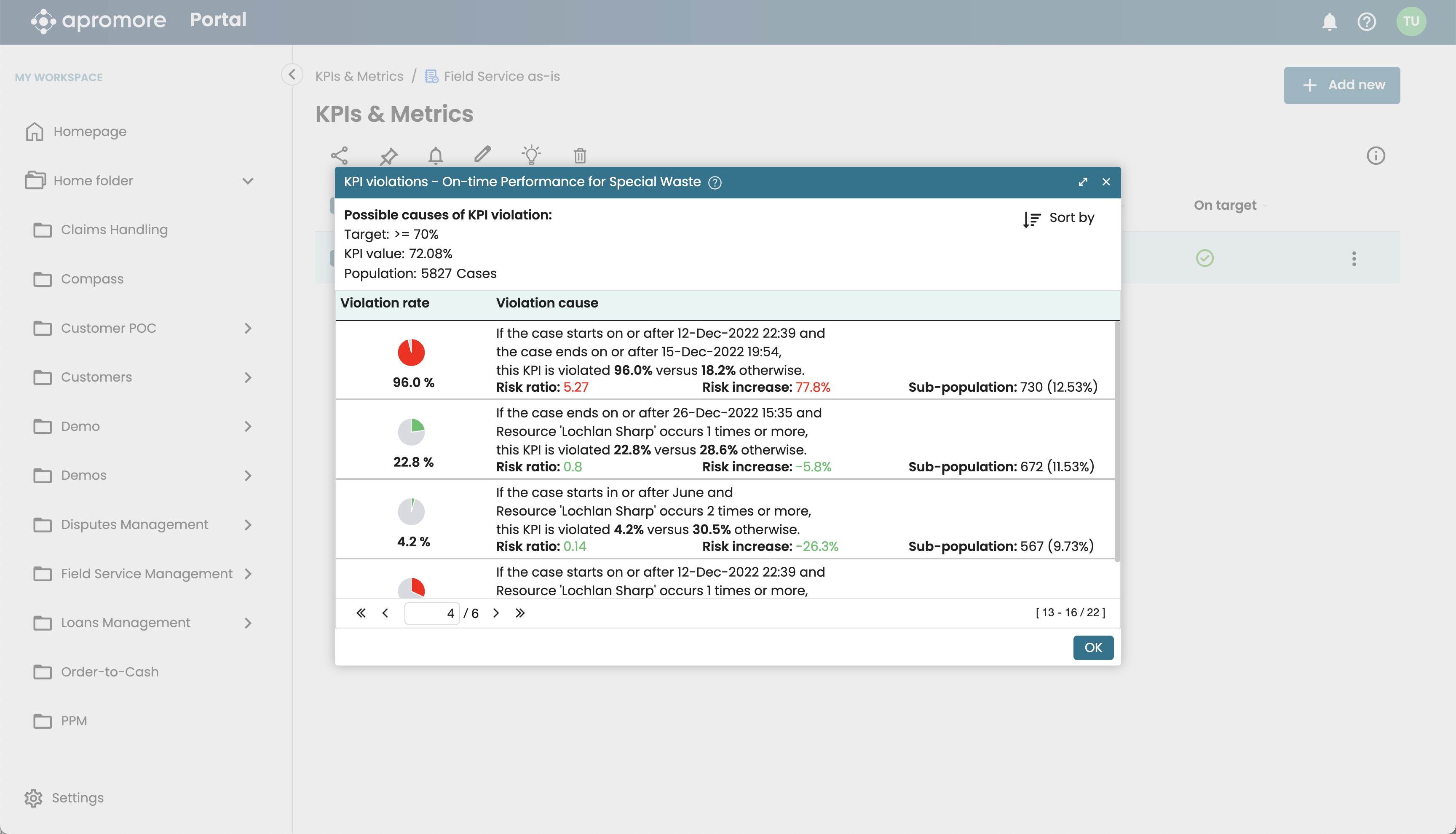

Once the process has been measured, the next step is to analyze the data and identify the root causes of the problems, such as bottlenecks, rework loops and other sources of waste. This can be done using a variety of statistical tools and techniques, including regression analysis, hypothesis testing, control charts, visual inspection via the use of multiple process perspectives (e.g. inspecting the roles and resources involved in a bottleneck activity), as well as using Apromore from Salesforce KPI Center.

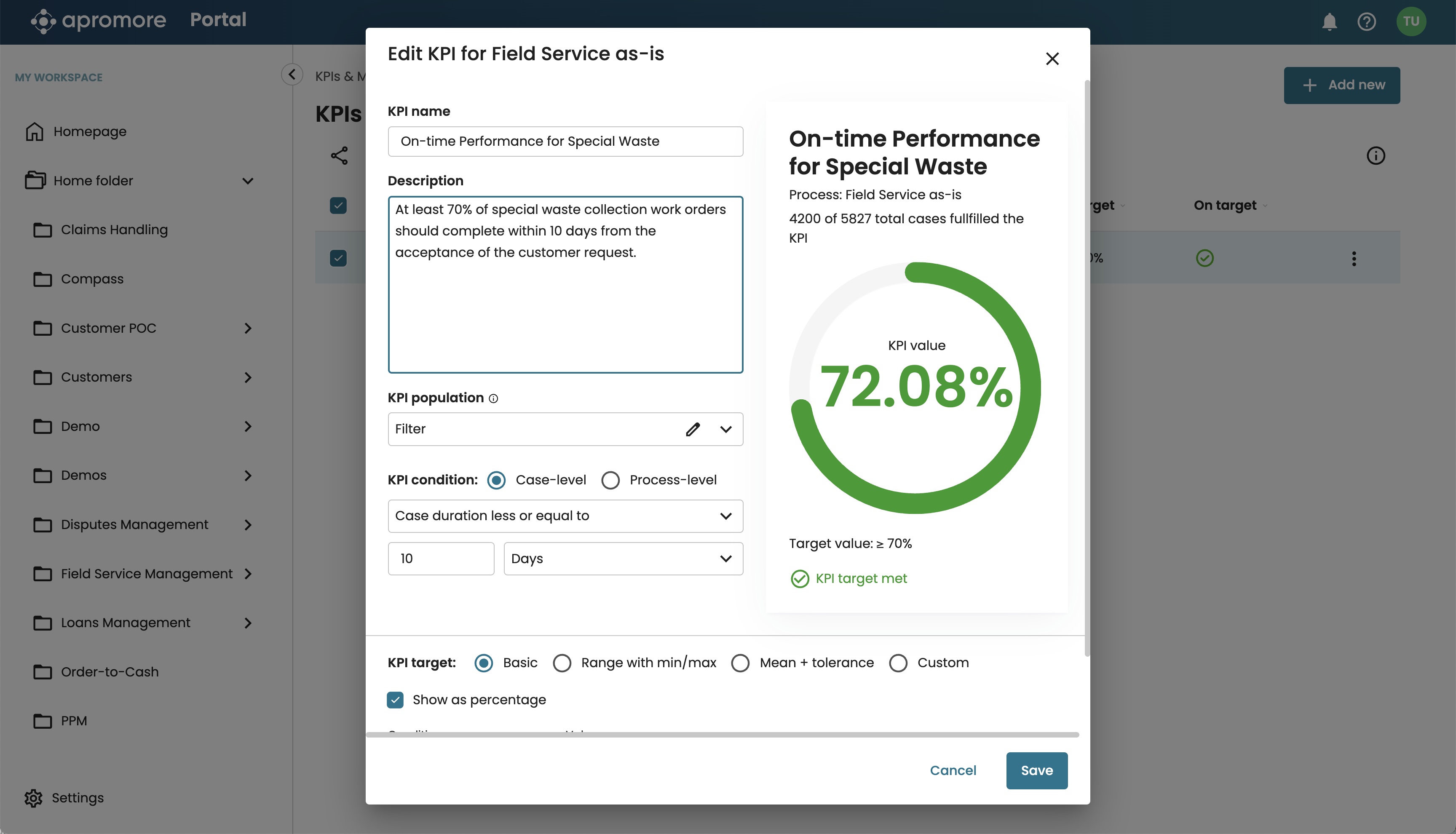

The Apromore from Salesforce KPI Center allows users to monitor and analyze key performance indicators (KPIs) in real-time. It provides users with a dashboard that displays KPIs for different processes, which can be customized based on the specific needs of the organization. It allows users to track metrics such as cycle time, throughput, case cost, that are critical to the success of Lean Six Sigma initiatives, which is essential for identifying areas of improvement and implementing effective solutions. These metrics can be composed to create KPIs, such as on-time performance, first-touch resolution, error or defect rate, with appropriate targets (e.g. at least 90% of the work orders should be completed on first touch).

When a process is falling behind its KPI targets, you can use Apromore from Salesforce’s root cause analysis to detect and address the bottlenecks, friction points, and sources of waste that are hampering the fulfilment of each KPI. Apromore from Salesforce’s root cause analyzer uses state-of-the-art AI techniques to scour through your business process execution data and find high-quality explanations for KPI violations, which you can connect to concrete improvement opportunities.

Improve

With the root causes of the problems identified, the next step is to develop and implement solutions to improve the process. Apromore from Salesforce can be used to simulate the impact of different solutions on the process performance before risking making changes in the real world. This can be done by automatically creating a "digital twin" model of the process and testing different “what-if” analysis scenarios to determine the best course of action. This not only allows creative and innovative improvements to be tested risk-free, but also ensures that improvements do not cause further problems down the process. That is, Apromore from Salesforce's simulation helps understand the impact of an improvement intervention on the process' cost, time, resource utilization and any other metric or KPI set by the user. This enables users to design and implement holistic improvements.

Control

Once the solutions have been implemented, the final step is to control the process to ensure that the improvements are sustained. This involves monitoring the process performance and implementing controls to prevent the reoccurrence of the problems. Also, by using the Apromore from Salesforce KPI Center in conjunction with the Lean Six Sigma methodology, organizations can achieve continuous process improvement and optimize their operations for maximum efficiency and effectiveness. Alerts and notifications can be set to notify relevant process stakeholders when KPI breach or are predicted to breach within a certain confidence level.

Apromore from Salesforce also offers AI-driven predictive analytics of live processes. For instance, the length of (cycle time) and outcome of individual cases can be predicted and if necessary, mitigating actions can be taken to ensure as many desired outcomes can be achieved as possible.

Using Apromore from Salesforce process mining with the Lean Six Sigma methodology can lead to significant process improvement. The use of Apromore from Salesforce enables organizations to identify inefficiencies and bottlenecks in their processes, while the Lean Six Sigma methodology provides a structured approach to process improvement. By following the DMAIC approach with Apromore from Salesforce, organizations can ensure that their process improvement efforts are focused and effective.

If you would like to see how Apromore from Salesforce can help you improve and monitor your business processes, please contact us.

Chris Godden

Chris Godden